3D printing is a rapidly growing technology that is changing the way we manufacture products. It is a process that involves building three-dimensional objects from a digital file. In this article, we will discuss what 3D printing is, how it works, and its advantages.

Table of Contents

What is 3D Printing?

3D printing, also known as additive manufacturing, is a process that involves building a three-dimensional object from a digital file.

This process involves layering material on top of each other until the object is complete. 3D printing technology has advanced significantly over the last few years and is now being used in many industries, including healthcare, automotive, aerospace, and architecture.

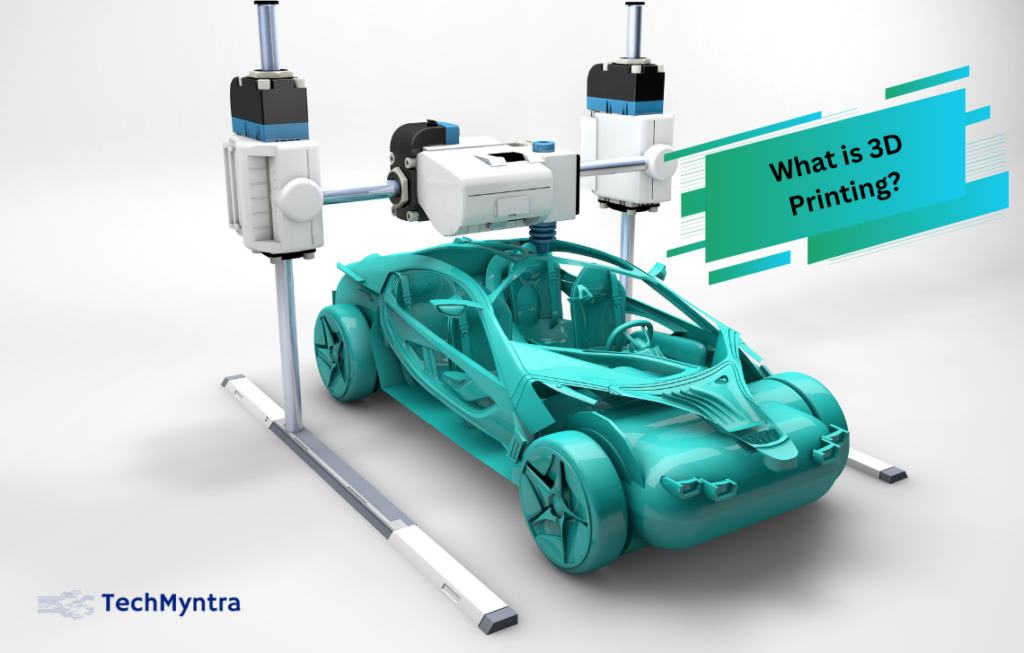

How Does 3D Printing Work?

The 3D printing process begins with a digital file, which is created using 3D modeling software. The file is then sent to a 3D printer, which reads the file and begins printing the object layer by layer. The printer uses various materials such as plastics, metals, and ceramics to build the object. The printer can also use different colors and textures to create a more realistic object.

There are several types of 3D printing technologies, but the most common method is called fused deposition modeling (FDM). In FDM, the 3D printer heats a plastic filament and extrudes it through a small nozzle. The nozzle moves back and forth across a build platform, creating each layer of the object. Once one layer is complete, the platform moves down slightly, and the printer adds another layer on top of the previous one. This process continues until the entire object is complete.

The 3D printer reads a digital file, typically in the form of a .STL file, which provides the instructions for building the object. The file includes a series of cross-sectional images of the object, which the 3D printer uses to build the object layer by layer. The software that accompanies the printer allows the user to customize the design and settings for the printer.

What Materials Can Be Used in 3D Printing?

3D printing can use a wide variety of materials, including plastics, metals, ceramics, and even food! The most common materials used in 3D printing are thermoplastics, which can be melted and extruded through a nozzle. These materials include ABS, PLA, PETG, and nylon.

What Are the Applications of 3D Printing?

3D printing has many applications across a variety of industries, including manufacturing, aerospace, automotive, healthcare, and education. In manufacturing, 3D printing is used to create prototypes, jigs, and fixtures, and even end-use parts. In aerospace and automotive, 3D printing is used to create lightweight parts with complex geometries. In healthcare, 3D printing is used to create custom prosthetics and implants. In education, 3D printing is used to teach students about design and manufacturing processes.

Advantages of 3D Printing

Cost-Effective: 3D printing can be more cost-effective than traditional manufacturing methods, especially when it comes to creating prototypes or small batches of products.

Customization: 3D printing allows for the creation of customized products. This is especially useful in industries like healthcare, where customized medical devices and implants can be created for individual patients.

Speed: 3D printing can be faster than traditional manufacturing methods, especially for small batches of products.

Reduced Waste: 3D printing only uses the amount of material that is needed to create the object, which reduces waste compared to traditional manufacturing methods.

Accessibility: 3D printing allows for the creation of products in remote locations where traditional manufacturing methods may not be available.

Design Flexibility: 3D printing allows for greater design flexibility, as complex shapes and geometries can be easily created without the need for specialized tooling or manufacturing processes.

Prototyping: 3D printing is an excellent tool for creating prototypes of products. With 3D printing, designers can quickly and easily create physical models of their designs, test them, and make necessary changes before moving to mass production.

Reduced Inventory Costs: 3D printing can help reduce inventory costs by allowing companies to produce products on demand. Instead of holding a large inventory of products, companies can use 3D printing to produce products as they are needed.

Sustainability: 3D printing can be a more sustainable manufacturing method than traditional methods, as it uses only the amount of material that is needed to create the object. This reduces waste and helps to conserve resources.

Educational Tool: 3D printing is an excellent educational tool, allowing students to learn about design, engineering, and manufacturing. It can also be used to create visual aids, models, and prototypes in various educational settings.

Personalization: 3D printing allows for the creation of highly personalized products that meet the unique needs of individual customers. This is especially important in the healthcare industry, where customized prosthetics and medical devices can improve patient outcomes.

Complexity: 3D printing allows for the creation of highly complex geometries and shapes that would be difficult or impossible to create with traditional manufacturing methods. This opens up new design possibilities and allows for the creation of products with intricate details and features.

Rapid Iteration: 3D printing allows for rapid iteration and refinement of designs, as changes can be quickly made and tested. This is especially useful in industries like product design and development, where speed and agility are critical to success.

Risk Reduction: 3D printing can help reduce the risk associated with product development by allowing for the creation of functional prototypes that can be tested and refined before moving to mass production.

On-Demand Manufacturing: 3D printing allows for on-demand manufacturing, which means that products can be produced quickly and efficiently in response to changing market demands.

Conclusion

3D printing is a rapidly growing technology that is changing the way we manufacture products. The process involves building a three-dimensional object from a digital file, and it has many advantages over traditional manufacturing methods, including cost-effectiveness, customization, speed, reduced waste, and accessibility. As 3D printing technology continues to advance, it will likely become an even more integral part of many industries.